Latest bPod® news

September 2014

bPod® introduces buildAbillionHomes

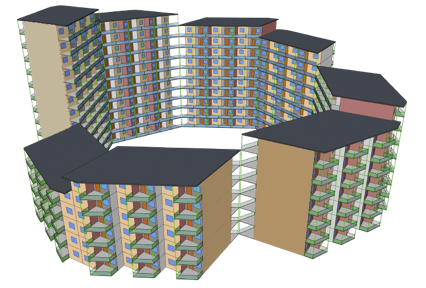

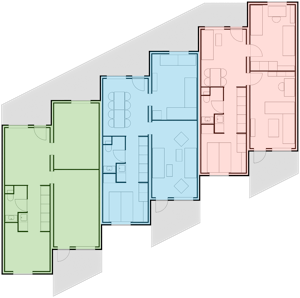

buildAbillionHomes is a concept which optimises the already frugal bPod building system for even more efficient mass production. This is aimed at supplying hundreds of millions of affordable quality homes world wide, especially in China and South East Asia.

buildAbillionHomes combines a flexible design with the proven economic and quality benefits of industrial mass production to meet those needs.

This brings to the building industry the large scale application of fully industrialised manufacturing which has never been done before.

The basic buildAbillionHomes unit provides a living space of just under 30 m². More room is achieved by connecting two or more units on a modular grid, resulting in home sizes of approximately 40 m², 50 m², 60 m², 70 m² and so on.

Simply put, this is “Live-In Lego” with all the benefits that mass production brings. With buildAbillionHomes, bPod aims to push savings on building cost beyond 30%, to 50% or more. That was done with cars, TVs, fridges, computers and everything else we buy. Now it will be done with homes.

Industrial production means that the more standardised the product, the more efficient the use of facilities and manpower and the greater the savings. But crucially, that does not have to lead to drab and dreary concrete deserts, as shown in this light and airy buildAbillionHomes design by bPod architect Ole Bjerre.

Back to Gallery Continue to Links

March 2014

bPod® on Ecobuild China

bPod participates in the Ecobuild China exhibition in Shanghai New International Expo Centre from 31st March to 3rd April:

Ecobuild China is the region's meeting place for the sustainable built environment industry and we look forward to welcoming you on stand W4E22.

October 2013

bPod® featured in Concrete Magazine

The October issue of concrete, the global magazine of The Concrete Society, shows bPod introducing concrete to off-site volumetric construction. Traditional off-site methods use light materials with attendant limitations on buildings and structures. In contrast, a bPod building, once assembled, has the same well-known strengths of a building made in traditional, heavy construction.

And then it has one added benefit: it’s cheaper to build. With large parts of the world in the grip of a recession, off-site contruction offers a way to lower construction costs that no subsidy scheme can achieve - without creating bubbles along the way.

Read the article here.

May 2013

bPod® test build in progress

bPod Denmark has established the first bPod build in the shape of a “test bench” which will be used to develop and optimise the bPod concept alongside planned customer deliveries.

The test bench is situated at the bPod Denmark production facility at Herlufmagle. First deliveries are scheduled for late 2013, and the test bench is also intended to give interested developers a chance to inspect the bPod product.

March 2013

bPod® shows a way to build the affordable homes people need

Savings on construction is better than subsidies at helping people find a home

In the UK, the Chancellor of the Exchequer introduced a mortgage guarantee scheme in his 2013 budget. He aims to create 570,000 new homes over three years and help first time buyers get on the housing ladder.

However, commentators say subsidies will only inflate property prices and much of the stimulus will be wasted on remortgaging or second homes. Many believe that government handouts do nothing to address the root problem which is one of high construction costs.

High building costs result in expensive developments which are out of reach of most first time buyers, and observers call for a new vision to address the housing crisis of today.

Such a vision does exist and is based on the simple fact that all other areas of industry have seen prices drop and quality improve through efficient manufacturing methods. Everything from cars to TVs, and even food, but not what matters most - our homes.

That is precisely what bPod sets out to change. With industrialised building methods achieving savings of up to a third of construction costs, the bPod vision means building half as much again with the same money and manpower.

This will genuinely help people on ordinary incomes find a home.

March 2012

Latest research supports ideas behind bPod® building method and business model

The Danish technology weekly “Ingeniøren” described in a recent feature article how the building trade has reached the limits of its potential because it has never been fully industrialised as have other areas of production.

The article was based on the author’s ph.d. thesis on the barriers to transforming the building industry. This lends scientific support to the fundamental ideas behind the bPod production method and business model which are expressed as follows in the introduction to the bPod website:

“Building practices have changed little for decades and will benefit from the introduction of modern production methods. The patented bPod building technology and its innovative business model do just that.”

February 2012

bPod® launched in Scandinavia through Nordic franchise and sales organisation.

Danish/Swiss entrepreneur Anders Kähler is awarded a master franchise for bPod in Sweden, Norway, Finland and Denmark. Kähler thereby continues his family’s 150-year tradition of innovation and product development in the building industry and is set to move multi storey construction into the 21st century.

Sub-franchises will be established in each country, the first one being bPod Danmark. Production start is planned for 2012 and other Nordic countries follow as soon as practicable.

At the same time, Kähler has signed a sales agreement with Danish estate agents Colliers International Danmark. With sales offices throughout the four countries, Colliers are uniquely placed to give the bPod system the best possible Scandinavian market exposure.

The use of licensing, franchising and sales agreements demonstrates the modernising bPod is planning for the building industry. We believe this will ensure a much wider and faster implementation than if the system were tied to traditional in-house production in a local market.

August 2011

bPod® presents draft project meeting 2015 low energy standards to leading Danish housing association KAB.

Energy standards in Danish residential building has gone from 70 kWh per square metre per year in 2008 to 53 kWh in the 2010 building regulations to an expected 30 kWh by 2015. Traditionally insulated multi-storey buildings can only just meet 53 kWh and it will be difficult to reduce this further due to structural constraints on the amount and type of outer wall insulation.

Outer walls in bPod construction have no limitations on the amount or type of insulation, and the latest bPod draft project for KAB, one of Denmark’s largest housing associations, shows additional building costs of less than 5% to insulate a 5-storey, 2,000 square metre residential building to 2015 standards. Such a building would still be 25% cheaper than a conventional construction built to 2010 standards.

No deductions are made for sustainable energy sources in these numbers, and wind turbines, solar panels or heat pumps can therefore further reduce the amount of conventional energy used.

May 2011

Building of social housing in Denmark is at an all-time low despite last year’s record level grants and long waiting lists. In Copenhagen alone, more than 100,000 people, and rising, are wait-listed.

The reason is building costs now exceeding the cost cap introduced by the Danish government to prevent social housing rents rising “higher than ordinary people can afford”.

bPod® offers a way out of this conundrum. With savings up to 30% compared to conventional construction, new builds can be completed within the cost cap. This is achieved through modernisation of the building process, partly by moving it largely indoors, partly through reducing waste and faults.

For some years, wooden cassettes have been used for much new construction. These are maintenance intensive and can be expected to have a relatively short life span, but even so they are now breaking the cost cap. In contrast, bPod uses durable, heavy materials like concrete in ways which combine modern energy and environmental concerns with quality of living, low maintenance and long life.

April 2011

In contrast, all bPod® buildings are fitted with high efficiency mechanical ventilation to all rooms (not just kitchens and bathrooms). This prevents mould formation and also reduces energy consumption. Mechanical ventilation with high heat recovery saves significant energy compared to “natural ventilation” where fresh air from outside has to be heated to room temperature.

February 2011

In contrast, bPod® buildings are constructed with a reinforced concrete framework which can be designed to withstand considerable earthquake forces. Even if a bPod building is damaged by an earthquake, possibly beyond repair, it will remain standing rather than collapse on its occupants.

This safety and strength is achieved without sacrificing the cost and time savings that bPod construction offers over traditional building, making it an ideal method for new construction in earthquake zones as well as rebuilding after earthquake disasters.

November 2010

The construction industry is one of the most dangerous and unhealthy for its employees, and Danish press recently reported 105 out of 195 building sites being shut down by Health and Safety due to serious breaches in many cases putting workers in direct danger of their lives.

In stark contrast to this traditional image of building, the bPod® system removes the risks and strains associated with working at great heights, outdoors and in all weather. By performing most of the construction work indoors and at ground level, heavy and damaging work is taken over by machines, and workers need rarely leave the safety of solid ground. Safety throughout the building process is not optional but is achieved and maintained through systems and methods built into the bPod technology from the start.

The patented bPod building technology not only offers financial savings of up to 30% on traditional building costs, but provides significant benefits for its workers, the environment and those who will eventually live in the buildings.

October 2010

Unlike most multi-storey construction, the bPod® technology favours underfloor heating for its greater thermal efficiency and better suitability to sustainable energy sources.

A report presented this month to the Nordic Passive House conference now shows the benefits of using the same underfloor pipes to lower floor temperatures in summer, acting as an energy efficient cooling system.

September 2010

Recycled paper insulation is offered as yet another alternative to mineral fibre in bPod® construction. Paper insulation uses less energy in its manufacture, further enhancing the green profile of bPod® buildings.

With bPod, multistorey buildings are for the first time able to meet low energy standards, due to the unique ability of bPod to construct wall cavities of any dimension and use a variety of insulation types.

August 2010

Use of the space age superinsulation material aerogel is being developed by bPod® as an alternative insulation material.

Aerogel insulates two to three times better than mineral fibres and therefore allows much thinner walls than would otherwise be possible in low energy buildings. This solves problems associated with reduced daylight and floor space in low energy construction.

Although aerogel is up to 50 times more expensive than standard insulation, bPod’s unique construction method retains much of its cost saving, and a bPod building using aerogel insulation is still cheaper to build than a standard insulated building in traditional construction.

March 2010

The patented bPod® technology is currently under development. When fully developed, the system will be licensed or franchised to building manufacturers and developers worldwide.

Interested parties can register with us now in order to receive progress reports and place themselves in pole position in their own market.

Although the building industry is hit by the present recession, we see this as the right time to develop new technology in readiness for an upturn. When that comes, the need to build economically and environmentally sound will be greater than ever, and bPod will be perfectly placed to meet that need.

bPod, build pod, build-pod, pod build, build, building, building technology, construction, volumetric, offsite, multi-storey, low-rise, lo-rise, medium rise, apartment, hotel, youth hostel, office, concrete, energy efficient, green, new way, superinsulation, aerogel, nanogel

Gestalt, Gebäude, Bautechnologie, Bau, mehrstöckig, Hochhaus, Wohnung, Hotel, Jugend-Herberge, Büro, Beton, Energiesparende, grüne, neue Methode

construction, bâtiment, technologie de la construction, construction, à plusieurs étages, en hauteur, appartement, hôtel, auberge de jeunesse, bureau, béton, performance énergétique, vert, nouvelle méthode, isolation maximum, aérogel, nanogel

byggeri, konstruktion, etagebyggeri, lejlighed, hotel, kollegie, kontor, beton, energi, energibesparelse, grøn, ny metode, superisolering